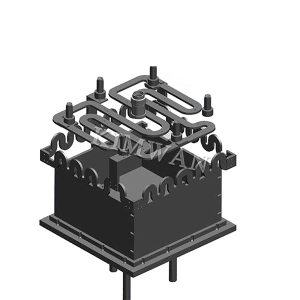

Graphite Parts for High-Temperature Furnaces

Graphite Parts for High-Temperature Furnaces are essential components in industries that rely on high-heat processing, such as metallurgy, ceramics, and aerospace. These parts, made from high-purity graphite, are designed to withstand the extreme temperatures and thermal stresses that are characteristic of high-temperature furnaces. Whether used as crucibles, trays, electrodes, or other furnace components, Graphite Parts for High-Temperature Furnaces offer unparalleled durability, thermal conductivity, and resistance to oxidation. Their unique properties make them the ideal material for ensuring the efficiency, longevity, and reliability of high-temperature processing systems, where precision and performance are paramount.

One of the key advantages of Graphite Parts for High-Temperature Furnaces is graphite’s excellent thermal conductivity. In high-temperature environments, efficient heat distribution is crucial for maintaining consistent temperature profiles and optimizing processing conditions. Graphite Parts for High-Temperature Furnaces are highly effective at dissipating heat, ensuring that the furnace operates at optimal temperatures and reducing the likelihood of hot spots or uneven heating. This capability is particularly important in industries like metallurgy, where the uniformity of temperature can significantly impact the quality and consistency of the final product, such as in metal casting or sintering.

In addition to thermal conductivity, Graphite Parts for High-Temperature Furnaces are also known for their remarkable resistance to thermal shock. In high-temperature processes, rapid temperature fluctuations can cause materials to crack or degrade, but graphite’s ability to expand and contract without cracking makes it ideal for use in such demanding environments. This resistance to thermal shock ensures that Graphite Parts for High-Temperature Furnaces can withstand the cyclical heating and cooling processes common in many industrial applications. Their ability to maintain their structural integrity over time contributes to the longevity and reliability of the furnace, reducing the frequency of maintenance and replacement.

Another advantage of Graphite Parts for High-Temperature Furnaces is their resistance to chemical attack. High-temperature environments often involve corrosive gases or reactive substances that can cause significant wear and tear on furnace components. Graphite, however, is highly resistant to oxidation and chemical erosion, which allows it to maintain its functionality even in harsh atmospheres. This durability makes Graphite Parts for High-Temperature Furnaces not only cost-effective but also essential for processes that require a high level of material stability, such as in the production of semiconductors, advanced ceramics, or metals used in aerospace applications.

In conclusion, Graphite Parts for High-Temperature Furnaces are indispensable in industries that require precise and reliable high-heat processing. Their superior thermal conductivity, resistance to thermal shock, and durability under harsh conditions make them ideal for ensuring efficient and long-lasting furnace operations. As industries continue to push the boundaries of high-temperature processing, Graphite Parts for High-Temperature Furnaces will remain a critical component in achieving optimal results, ensuring the longevity of furnace systems and the quality of the final products.