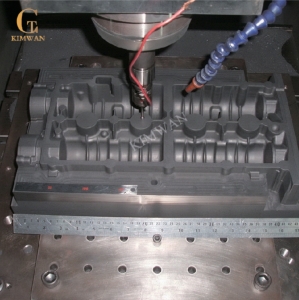

Graphite molds for Electrical Discharge Machining (EDM Graphite) are ideal for processing parts with internal sharp angles, complex shapes, and deep-cut sections. Using graphite electrodes with high-quality EDM equipment enhances production efficiency and reduces costs for lower mold parts, ensuring consistent quality across similar molds.

Graphite electrodes offer significant advantages over copper in EDM applications, such as lighter weight, faster discharge speed, high density with low wear rate, and low thermal expansion. These qualities of graphite significantly reduce the costs of mold manufacturing in EDM while maintaining or even improving quality standards.