Fuel Cell Bipolar Plates

The fuel cell bipolar plates developed by Kimwan adopt a new type of binder in the processing, so the fuel cell bipolar plates have excellent electrical conductivity and corrosion resistance, high mechanical strength, and good gas seal. Thanks to the direct hot press forming method, the production process is simplified and the processing cost is reduced.

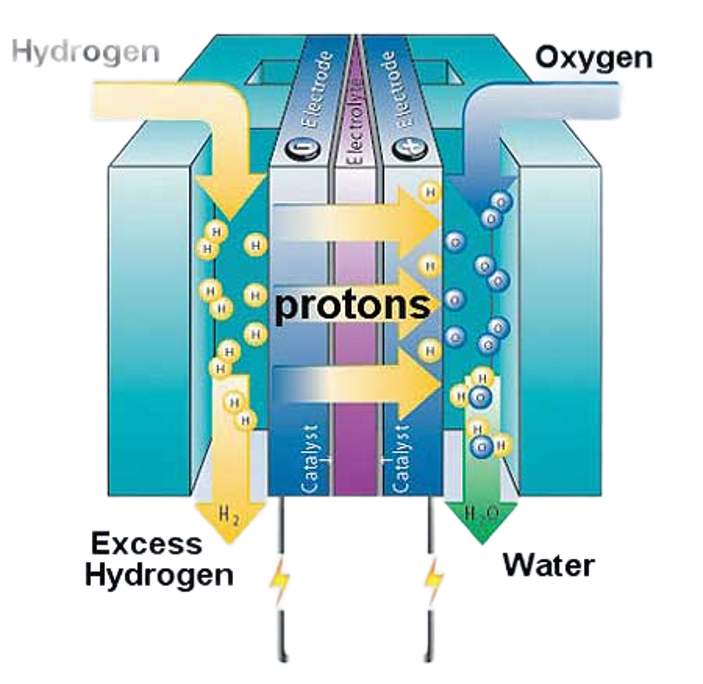

The bipolar plate is a key component in the hydrogen fuel cell stack and forms a stack together with membrane electrodes, current collector plates, insulating plates, end plates, etc.

graphite powder and resin are mixed and prepared, then the mixed materials and molds are processed, using the polymer’s melting temperature and a certain pressure, so that the powder flows in the mold and fills the entire container, curing and demolding to obtain the Fuel Cell Bipolar Plates

Molding process for manufacturing bipolar plates can effectively solve the problems of high processing costs and large-scale production. We are currently developing this process.

Fuel Cell Bipolar Plates

G3-01 is obtained by impregnating high-quality graphite with resin and then by machining, which not only ensures strict dimensional standards, but also possesses high electrical conductivity and mechanical strength; it can be used in proton exchange membrane fuel cell stacks, which guarantees high performance and longer service life.

Product Physical and Chemical Properties

| 检验项目 Test Item | 单位 Unit of Measure | 数值 Numerical Value |

| 密度 Density | (g/cm3) | >1.9 |

| 抗弯强度 Flexural Strength | (MPa) | >45 |

| 剪切强度 Shearing Strength | (MPa) | >15 |

| 抗压强度 Compressive Strengths | (MPa) | >130 |

| 肖氏硬度 Shore Hardness | HRS | >80 |

| 电阻率 Resistivity | (mΩ*cm) | <1.1 |

| 电导率 Conductivity | (S/cm) | >900 |

Dimensional Machining Accuracy

| 外观参数 Appearance Parameters | 单位 Unit of Measure | 尺寸加工精度 Dimensional Machining Accuracy |

| 极板长 Polar Plate Length | mm | ±0.1 |

| 流场脊宽度 Width of Flow Field Ridge | mm | ±0.05 |

| 流场槽宽度 Width of Flow Field Slot | mm | ±0.05 |

| 流场槽深 Flow Field Slot Depth | mm | ±0.05 |

| 密封槽宽度 Sealing Groove Width | mm | ±0.05 |

| 密封槽深度 Sealing Groove Depth | mm | ±0.03 |

| 极板厚度 Polar Plate Thickness | mm | ±0.05 |

Molded Composite Bipolar Plate Product Introduction

G5-01 is obtained by first mixing optimized graphite powder, resin, and other auxiliary materials. Lastly, the powder is hot-pressed, which ensures strict dimensional standards while possessing high electrical conductivity and mechanical strength in a single molding. It can be used in proton exchange membrane fuel cell stacks to ensure high performance and longer service life.

Product Physical and Chemical Properties

| 检验项目 Test Item | 单位 Unit of Measure | 测试值 Test Value |

| 厚度偏差 Thickness Deviation | mm | ±0.02 |

| 密度 Density | g/cm3 | >1.9 |

| 抗弯强度 Flexural Strength | MPa | >30 |

| 剪切强度 Shearing Strength | MPa | >15 |

| 电导率 Conductivity | S/cm | >150 |

| 电阻率 Resistivity | mΩ*cm | <66 |

Liquid Flow Battery Graphite Plate

The application of energy storage technology can smooth the output of renewable energy, improve the grid connection rate, reduce the abandonment rate, and can be widely used in all aspects of modern power system, including generation, transmission, distribution, transformation and utilization. Among many electric energy storage technologies, flow battery has become one of the mainstream technologies with the advantages of high safety, large energy storage capacity, power and energy decoupling, long life and relatively friendly environment. It realizes the mutual conversion of electric energy and chemical energy through the reversible redox reaction of dissolved active substances.

Graphite plate has the advantages of high chemical stability, good corrosion resistance, high electrical conductivity and low density.Our company has mature graphite plate production and processing technology.

As an important part of the liquid current battery, bipolar Fuel Cell Bipolar Plates separate and connect the batteries in series, conduct current, and provide structural support for the power stack. Therefore, the bipolar plate needs to have high electrical conductivity, mechanical strength, airtightness and corrosion resistance, and at the same time, it should have the characteristics of easy processing and low cost.

Machined Bipolar Plates Product Profile

G6-01 is an isostatically pressed graphite sheet impregnated with resin to provide high mechanical strength, low permeability, high electrical conductivity, and resistance to strong acids to ensure high performance and longer service life.

Product Physical and Chemical Properties

| 检验项目 Test Item | 单位 Unit of Measure | 数值 Numerical Value |

| 密度 Density | (g/cm3) | >1.9 |

| 抗弯强度 Flexural Strength | (MPa) | >45 |

| 剪切强度 Shearing Strength | (MPa) | >15 |

| 抗压强度 Compressive Strengths | (MPa) | >130 |

| 腐蚀电流密度 Corrosion current density | μA/cm2 | <12 |

| 电阻率 Resistivity | (mΩ*cm) | <1.1 |

| 电导率 Conductivity | (S/cm) | >900 |

Other Kimwan Carbon Products Suggestions: